Whether you are a roofing company, managing a building, in need of a roof replacement Winston Salem, working with solar panels, inspecting for an insurance claim, or any other number of reasons, it makes sense to consider using drones for roof inspections for a range of benefits, including safety, cost, and time.

The old traditional method of inspecting roofs

Until recent innovations, there was just no way around it. If you wanted to do a proper roof inspection and analysis, you had to:

Climb up on a ladder…

You might take photographs,

or even take core samples for the final roof report and remediation plan.

Drone missions planning

This is no different from the traditional approach roofers and project managers have used for decades, but now it’s pinning waypoints, setting altitudes, confirming airspace and more.

Fly the drone

The next stage in the workflow is arriving on site and conducting the flight where possibly hundreds of images are captured before the flight is completed. The flight aspect of the workflow is about minimizing time on the roof, letting you get onsite, collect a high-quality dataset, and then move on. Some of the best drones used today for roof inspection include:the DJI Inspire 2

and the Autel Robotics X-Star Premium Drone.

Whichever drone you choose, it’s important that you get one that has not only high quality cameras, but a range of sensors as well (such as thermal). Using an inexpensive consumer drone might be fine for some applications, but to get the best images, data, and analysis, it’s best to use one of the better commercial-grade models on the market.

Collect drone data

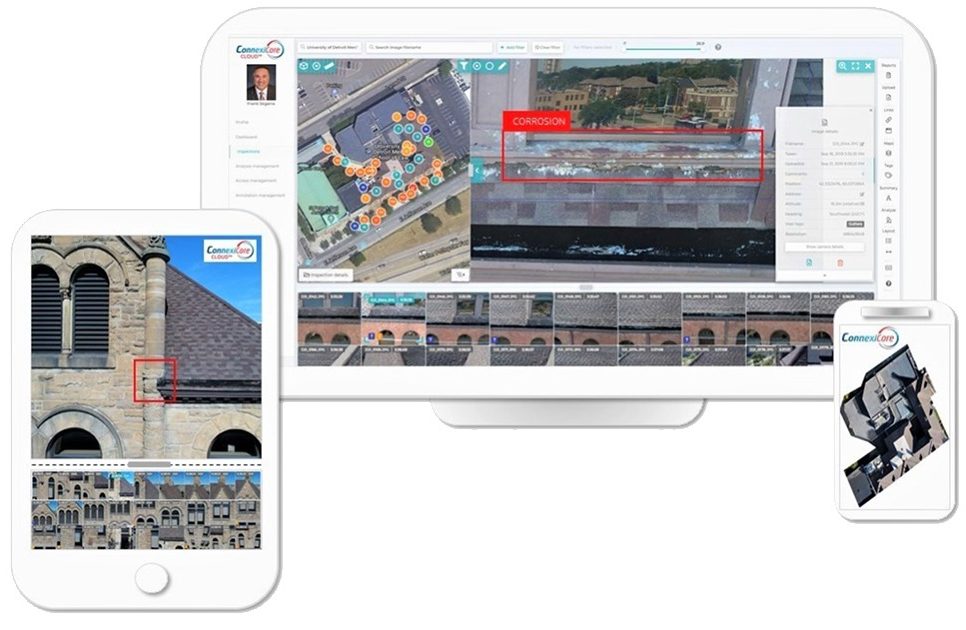

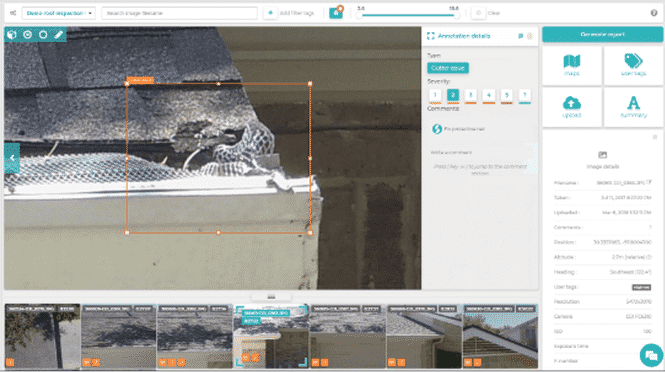

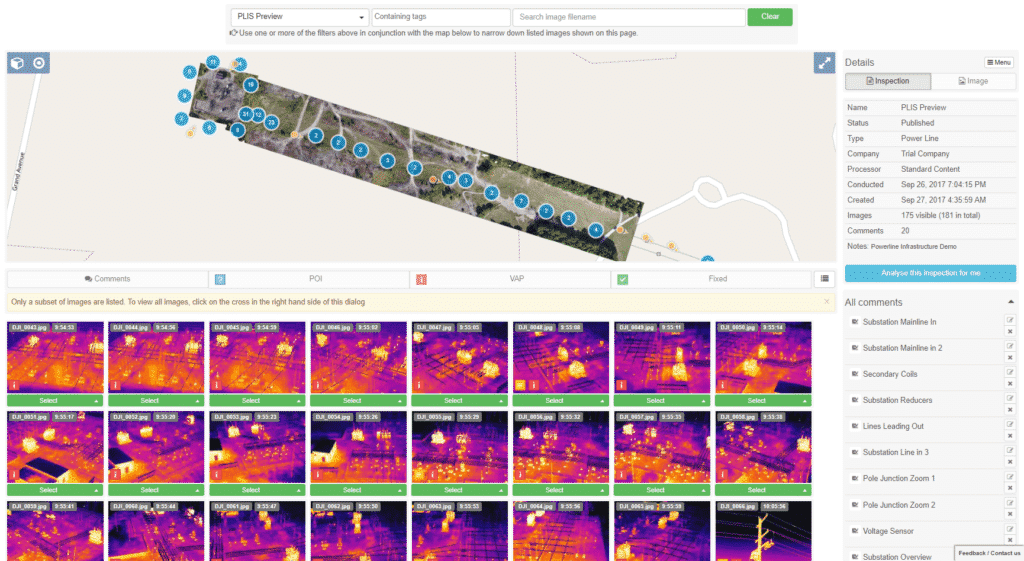

Drones can generate a variety of data types. This could include high-resolution roof images that are date and geo-tagged to pinpoint and annotate for expert inspection.

Video flyovers of the roof to better understand the full roof layout, and generate orthomosaic data for visual interactive maps so you can interact with it in the same powerful, intuitive way that you can with Google Maps.

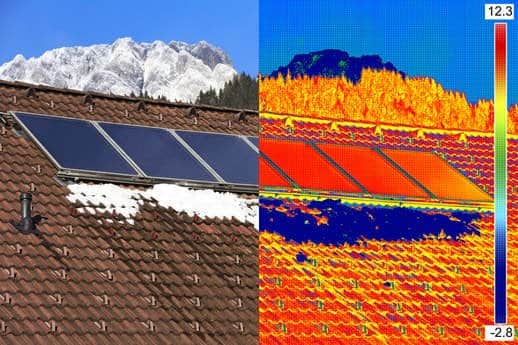

Drones can also deploy thermal cameras, which have become a powerful tool for conducting roof inspections. Since wet areas on a roof retain heat longer than dry areas, thermal imagery can detects temperature differences and help inspectors pinpoint areas of concern that warrant a closer look.

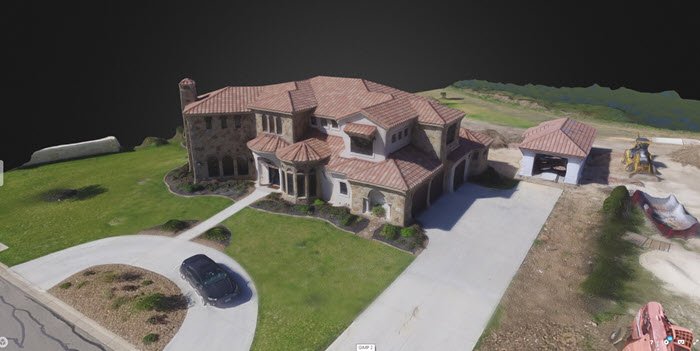

Point cloud data, so that you can create 3D models for advanced offsite review.

Drone data analysis

It’s not really about the drones, it’s about the data and how to leverage it. But data alone is useless unless it can be processed into actionable business insights. Just having 500 roof images, or even point cloud 3D models doesn’t help you achieve your objectives. You need answers based on data. For example,- How long is this roof edge?

- What is the surface area of this roof plane?

- What are the damages or roof obstructions?

It’s now easier than ever to share images and insights with other stakeholders, allowing for faster consensus and decision-making.

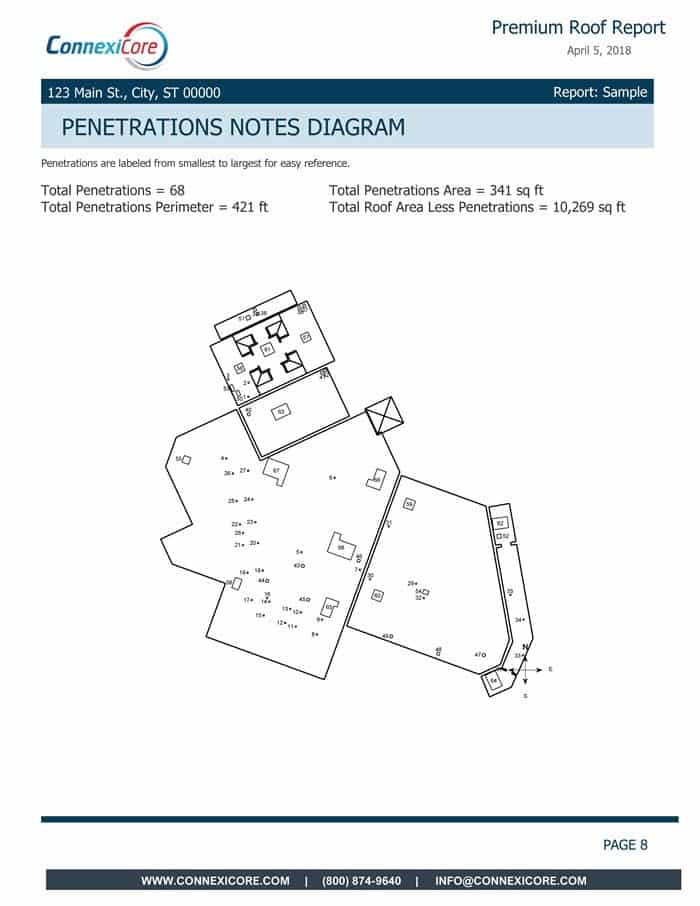

Generating a roof inspection report

With all the roof inspection data collected and analyzed, the final stage in the drone roof inspection workflow is the report. A proper report will also provide the images and .DXF files that will allow you to collaborate, share and integrate into CAD software.

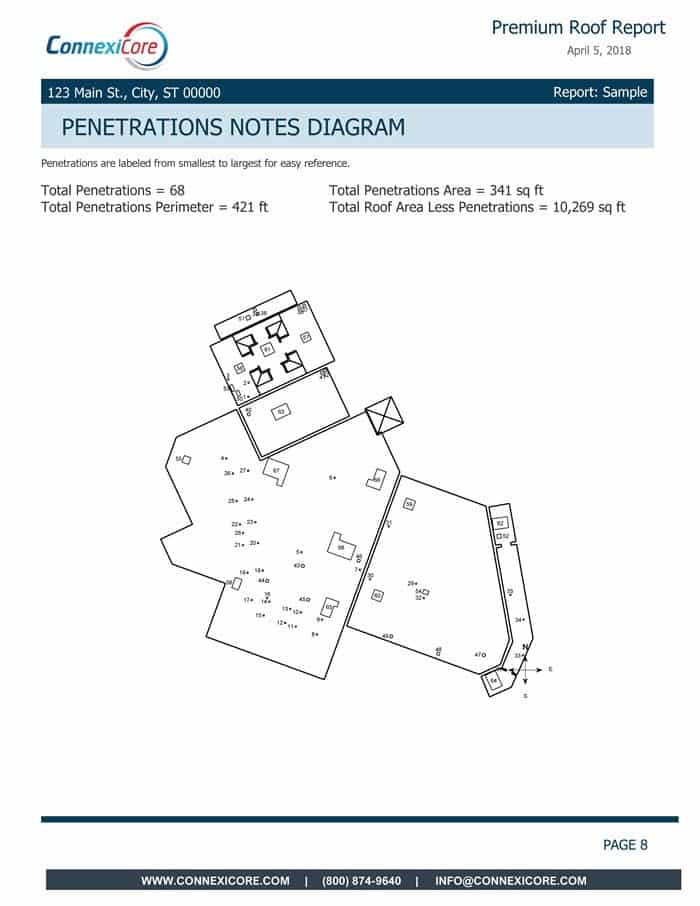

Some of the critical and useful information you might find in a roof report could include:

- Roof geometry

- Square footage

- Roof features

- Classification of edges

- Pitch

- Surface area

- Slope

When working on a complex roof with lots of facets, planes, and edges it can be challenging to get to all the edges, measure them precisely, and consistently get the tape measure in the right place every time. Drones can create these measurements automatically and consistently.

Roof inspection safety

It’s been said that robots—and drones are basically flying robots—are well-suited to do jobs that are “dirty, dull and dangerous”.

While there are many dangerous jobs in this world, among the ones we’re most likely to encounter are inspecting roofs. In addition, when workers are on ladders, you need additional workers for ladder-assist.

“Height increases danger—and roofing is an occupation where elevation is part of the job description.”

Conclusion

The recent convergence of commercial-grade drones and cloud-based drone data platforms have made it possible for drones to create an easier and more reliable method for roof inspections. Whether you purchase a drone to fly missions yourself or hire a drone roof inspection company, many industries are now leveraging the benefits of this new technology, including better data, a much safer work environment, and a lower overall roof inspection cost.

Frank Segarra

Frank Segarra is the Senior Vice President of Sales at Volatus Unmanned Services. He has over 30 years of IT, telecommunications and aviation industry experience and was a US Navy aircraft carrier airman specializing in Avionics Engineering. As a thought leader in drone technology, Frank was invited to be a founding member and co-chair of the CompTIA Drone Advisory Council. and is on the Board of Advisors for the PA Drone Association.